How Robotic Welding is Transforming Manufacturing

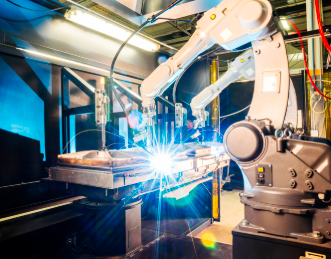

The manufacturing industry is changing fast, and robotic welding is leading the way. By working quickly, accurately, and consistently, robots help manufacturers produce high-quality welds while reducing mistakes and costs. They also improve workplace safety by handling dangerous tasks, allowing skilled workers to focus on more complex jobs.

As more industries adopt robotic welding, it is transforming how products are made and setting new standards for efficiency. This article explores how robotic welding is shaping the future of manufacturing.

What Is Robotic Welding?

Robotic welding uses automated robots to perform precise, efficient, and consistent welds. Robots work longer with fewer mistakes and less material waste than humans. Advanced systems can mimic skilled human techniques, combining expertise with robotic accuracy to boost productivity, ensure uniform weld quality, and raise manufacturing standards.

Key Advantages of Robotic Welding

- Increased Productivity and Efficiency:

Robotic welding works faster and more efficiently than manual welding. Humans are active only 10–30% of the time, while robots can operate 50–80% in non-serial production and up to 90% in serial production. One robotic welding cell can replace up to five human welders. For example, General Motors increased productivity by 30% and cut operational costs by 20%. Continuous operation allows robots to maximize production speed and throughput.

- Consistent Quality and Precision:

Robots perform welds with high accuracy and consistency, producing uniform, defect-free results. This reduces variation, improves product reliability, and lowers costs. For example, Fendt cut production costs by 25% and sped up manufacturing by 15% using robotic welding. Real-time monitoring also helps detect problems immediately, further ensuring quality.

- Reduction in Waste and Consumable Usage:

Robots precisely control welding parameters, using only the material needed for each weld. This minimizes over-welding, spatter, and material consumption. New Holland Agriculture reduced material waste by 22%. Consistent quality also lowers rework, saving materials, labor, and boosting overall efficiency.

How Robotic Welding is Changing Manufacturing

Robotic welding is changing manufacturing by automating welding tasks across different industries. This makes production faster, improves weld quality, and creates safer workplaces. Here’s how it’s used in key sectors:

- Automotive Industry

In the automotive industry, robotic welding is used to assemble car bodies, frames, and other parts, providing fast, precise, and consistent results.

- Aerospace and Defense

Robots weld aircraft parts accurately and reliably, ensuring they meet strict safety and quality standards.

- Construction and Heavy Fabrication

Robotic welding is used to build steel structures, bridges, and buildings. Robots can handle heavy components and create strong, durable welds, which are critical for safety and stability.

- Consumer Electronics

Robots assemble metal parts in devices like smartphones, tablets, and computer cases. Using automation makes production faster and keeps quality high.

- Medical Devices

Robotic welding makes surgical instruments and medical devices with precise, safe, and reliable welds.

- General Manufacturing

In general manufacturing, robotic welding is used for appliances, electronics, and other fabrication. Robots can handle different materials and welding methods, making them versatile for many production needs.

Robotic welding enhances productivity, ensures consistent quality, and promotes safer workplaces, helping manufacturers remain competitive.

How Robotic Welding Enhances Production

Robotic welding transforms manufacturing by combining automation, advanced sensors, data analytics, and flexibility. Key benefits include:

- Seamless Integration into Assembly Lines

Robotic welders fit easily into existing production lines, quickly adapting to workflows. This reduces downtime and accelerates the return on investment.

- Advanced Sensors and Quality Control

Equipped with infrared, ultraviolet, and visual sensors, robots monitor welding parameters in real time. AI and deep learning detect defects instantly, ensuring precise, consistent welds and reducing errors and rework.

- Data-Driven Continuous Improvement

Robotic systems collect production data to track quality, optimize processes, and schedule predictive maintenance. Analytics help anticipate issues, make proactive adjustments, and continuously improve efficiency.

- Flexibility for Small-Batch and High-Mix Production

Robots handle multiple product types without major reconfiguration. Modular design, smart tooling, and AI-driven automation allow quick adjustments, making them ideal for small-batch or high-mix production.

Robotic welding improves manufacturing by making it faster, more consistent, adaptable, and easier to scale.

Challenges and Considerations in Robotic Welding

Robotic welding brings many benefits, there are some challenges manufacturers need to keep in mind:

Common Challenges

- High Initial Cost: Buying robotic systems, including robots, controllers, and setup, can be very expensive. This cost may be a barrier for small and medium-sized businesses.

- Complex Programming and Maintenance: Robots require skilled operators to program them and regular maintenance to keep them running. Issues like worn welding tips or broken parts can interrupt production.

- Limited Flexibility: Robots excel at repetitive tasks but may struggle with complex, customized, or constantly changing parts.

- Space and Integration Needs: Installing robots requires enough physical space and careful planning to fit them into existing production lines without causing disruption.

- Workforce Training and Safety: Operators must be trained not only in welding but also in programming, maintaining, and safely operating robotic systems. Proper training is essential to prevent accidents and ensure smooth operation.

Key Considerations for Success

- Careful Planning: Organize production workflows and choose the right equipment to prevent mistakes and keep operations running smoothly. Proper planning ensures the robotic system meets production needs efficiently.

- Regular Maintenance: Perform routine checks and servicing on robots to prevent breakdowns, reduce downtime, and extend their lifespan. Regular maintenance keeps the system reliable and productive.

- Scalability: Plan for future growth so that the robotic system can be easily upgraded or expanded as production demands increase. This allows manufacturers to adapt without major disruptions or extra costs.

Careful planning helps manufacturers get the most from robotic welding, improving productivity and quality.

Future Trends in Robotic Welding

Robotic welding is evolving through advanced technologies and smarter automation, making manufacturing more efficient, precise, and flexible. Key trends include:

- Collaborative Robots (Cobots): Work safely alongside humans, automate repetitive tasks, and allow operators to focus on complex work.

- AI and Machine Learning: Detect welding defects in real-time, improve quality control, and reduce errors.

- Data-Driven Manufacturing: Use production data for process optimization, predictive maintenance, and better decision-making.

- Advanced Welding Techniques: Methods like laser, friction stir, and ultrasonic welding allow for very precise welds while causing little to no distortion to the material.

- Modular and Scalable Automation: Allows gradual adoption of robotic systems, reducing costs and enabling expansion as production needs grow.

- Market Growth: Increasing demand for automation and precision is driving widespread adoption and innovation in robotic welding.

Robotic welding is evolving to be smarter and more flexible, enhancing productivity, quality, and safety in modern manufacturing.

Conclusion: Robotic Welding in Manufacturing

Robotic welding is revolutionizing manufacturing by combining speed, precision, and consistency with automation and advanced technologies. It enhances productivity, ensures consistent quality, reduces waste, and improves workplace safety, allowing skilled workers to focus on more complex tasks. Robots provide faster, more reliable, and scalable production across industries while maintaining high quality.

Although challenges like high initial costs, programming complexity, and limited flexibility exist, careful planning, regular maintenance, and scalable implementation help manufacturers maximize the benefits. Looking ahead, trends such as collaborative robots, AI-driven quality control, data-driven manufacturing, advanced welding techniques, and modular automation are making robotic welding smarter, more adaptable, and integral to modern production.

Robotic welding not only transforms how products are made but also sets new benchmarks for efficiency, quality, and safety, ensuring manufacturers stay competitive in a rapidly evolving global market.