Understanding the Role of Fabric Density in Construction Projects

Introduction

In modern civil engineering and construction, materials used for soil stabilization and erosion control must meet specific quality standards. One of the most essential materials that fulfill these requirements is geotextile fabric. These fabrics are used in a wide range of applications, including road construction, drainage systems, and slope stabilization. Among the various factors determining their performance, geotextile gsm is one of the most significant. Understanding what this measurement represents and how it impacts construction projects is crucial for selecting the right material.

What Is Geotextile Fabric

Geotextile fabric is a synthetic material designed to improve soil strength and prevent erosion. It acts as a protective barrier, separating, filtering, and reinforcing soil in construction environments. These fabrics are commonly made from polypropylene or polyester, materials known for their durability and resistance to environmental factors.

There are two main types of geotextiles: woven and non-woven. Woven fabrics are created by interlacing yarns in a crisscross pattern, providing high tensile strength. Non-woven fabrics, on the other hand, are manufactured through bonding fibers together using heat, chemicals, or needling. Each type serves specific functions depending on the project requirements.

See also: Optimizing Workforce Management for Singapore Businesses

Understanding the Meaning of GSM in Geotextiles

The term geotextile gsm refers to “grams per square meter,” which is a unit of measurement that indicates the fabric’s weight and density. In simple terms, it tells how heavy or thick the material is over a standard area. A higher GSM value generally means a denser and stronger fabric, while a lower GSM indicates a lighter and more flexible one.

This measurement is an important indicator of fabric performance. For instance, a lightweight geotextile with 100–200 GSM may be ideal for garden landscaping or filtration, whereas a heavy-duty fabric with 400–600 GSM is more suitable for road construction or retaining walls.

Importance of Geotextile GSM in Engineering Applications

The geotextile gsm determines the functionality and strength of the geotextile. Here are some key reasons why it plays a crucial role in project success:

1. Strength and Durability

Higher gsm fabrics are thicker and can endure heavy loads, making them suitable for applications involving vehicle traffic or soil pressure. They are resistant to puncture and mechanical damage during installation, ensuring long-term performance.

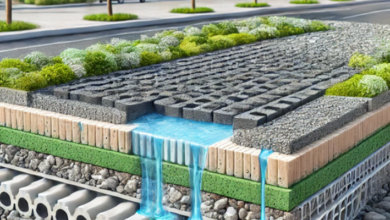

2. Filtration and Drainage

For drainage and filtration purposes, the gsm value affects how water and soil particles pass through the fabric. Lower gsm fabrics allow higher permeability but may not block fine particles effectively. Heavier gsm fabrics, with smaller pore sizes, provide better filtration while maintaining adequate water flow.

3. Soil Separation

In road and railway construction, geotextiles are used to separate different soil layers. The right gsm ensures that fine soil does not mix with gravel or aggregate layers, thus maintaining the structure’s integrity.

4. Erosion Control

When used on slopes, riverbanks, or coastal areas, the gsm of the fabric contributes to erosion control. A high gsm fabric provides strong protection against the movement of soil and sediment due to wind or water flow.

Types of Geotextile Fabrics Based on GSM

Different gsm ranges correspond to specific applications. Below is a general classification that helps determine which type to use for a particular project:

Light GSM (100–200)

- Used in small-scale landscaping projects.

- Ideal for weed control and simple drainage layers.

- Provides flexibility and easy installation.

Medium GSM (200–400)

- Commonly used in road and pavement foundations.

- Balances filtration, separation, and reinforcement functions.

- Effective for moderate load-bearing applications.

Heavy GSM (Above 400)

- Designed for highways, embankments, and large infrastructure.

- Withstands high mechanical stress.

- Offers long-term reinforcement and soil stability.

Factors to Consider When Selecting Geotextile GSM

Choosing the right gsm requires understanding the conditions of the project and the environment. Here are several factors to consider:

1. Type of Soil

Clay soils require stronger, heavier fabrics to resist deformation. Sandy soils may need lighter fabrics that allow better water permeability.

2. Load Requirements

The load exerted by vehicles, equipment, or soil determines the gsm required. For heavy loads, a higher gsm is recommended to prevent tearing or stretching.

3. Environmental Exposure

Projects exposed to sunlight, chemicals, or moisture require fabrics with adequate UV resistance and chemical stability. These features are often enhanced in higher gsm materials.

4. Functionality

Whether the goal is filtration, separation, or reinforcement, the gsm must be selected accordingly. Filtration may require medium gsm, while reinforcement may demand heavy gsm fabrics.

Testing and Quality Standards

Manufacturers test geotextile fabrics based on international standards to ensure quality and consistency. These tests include tensile strength, puncture resistance, permeability, and thickness. The gsm value is measured using specialized equipment to confirm that it meets the required specifications for its intended application.

Standard organizations like ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization) define methods for accurately testing geotextiles. Adhering to these ensures that the materials perform as expected under various conditions.

Advantages of Using the Correct GSM

Selecting the right geotextile gsm offers multiple advantages:

- Increases the structural stability of foundations and embankments.

- Enhances drainage and filtration efficiency.

- Reduces soil erosion and environmental damage.

- Extends the service life of roads and pavements.

- Ensures cost-effectiveness through durable performance.

Common Mistakes in GSM Selection

A common mistake is choosing a fabric without considering the project’s stress conditions. Using a low gsm material in high-pressure environments can result in premature damage or failure. Conversely, selecting an excessively high gsm when it’s not necessary increases costs without additional benefit.

To avoid such mistakes, engineers should assess soil type, load distribution, and environmental exposure before making the final selection.

Applications of Geotextiles in Different Industries

The use of geotextiles has expanded across multiple sectors beyond traditional construction. They are now used in agriculture for soil stabilization, in coastal engineering for erosion control, and in environmental projects for landfill protection. The gsm value determines their adaptability in each of these sectors.

For instance, in agriculture, lower gsm fabrics allow water to drain efficiently while preventing soil mixing. In coastal projects, higher gsm materials provide the strength needed to withstand wave impact and protect shorelines.

Conclusion

Geotextile fabrics have become an essential part of modern infrastructure and environmental engineering. The measurement known as geotextile gsm serves as a key indicator of fabric quality and suitability. By understanding gsm, engineers, architects, and contractors can make informed choices that enhance durability, cost efficiency, and performance.

Selecting the right gsm ensures that projects remain stable and sustainable for years to come, making it a vital factor in every phase of construction planning and execution.