Biaxial: The Science of Two-Directional Strength

In the field of engineering, materials science, and manufacturing, the term “biaxial” holds significant importance. Derived from Latin, where “bi-” means “two” and “axial” refers to axes, the term essentially describes properties, motions, or systems that operate along two distinct axes. Whether it is used in textiles, polymers, geosynthetics, medical devices, or mechanical systems, biaxial behavior is crucial for ensuring uniform performance, durability, and safety.

This article delves into the concept of biaxial as applied across multiple industries, its advantages, and how understanding two-axis dynamics can lead to more robust and efficient products and structures.

What Does Biaxial Mean?

At its core, biaxial refers to any object or system that has properties, movements, or behaviors in two perpendicular directions. These directions are usually at right angles (90 degrees) to each other. This term is widely applied in material testing (e.g., biaxial stress tests), mechanical components (e.g., biaxial hinges), manufacturing processes (e.g., biaxial stretching), and even in aerodynamics and optics.

In contrast to uniaxial, which involves a single direction or force path, biaxial systems are designed to respond equally or appropriately to forces or motions from two orthogonal directions.

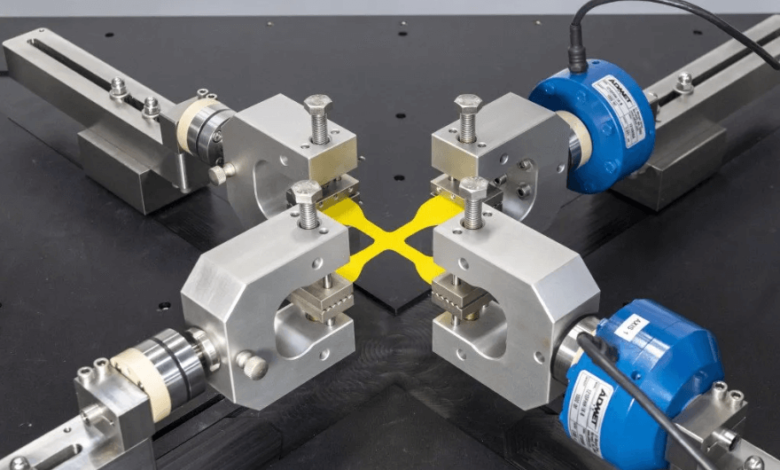

Biaxial in Material Testing

For example, in the case of a thin membrane or sheet used in packaging, both the width and length may be stretched or compressed at the same time to assess durability.

Key applications of biaxial testing include:

- Polymer Films: Biaxial orientation increases tensile strength and clarity.

- Biomedical Membranes: Simulates conditions like those in the human heart valve or skin.

- Elastomers and Composites: Ensures the materials behave well under multi-directional loads.

By using biaxial testing, manufacturers can design materials that perform predictably in complex real-world environments.

See also: Sheet Metal Bending: Techniques, Tools, and Applications

Biaxial in Geosynthetics

In civil engineering, biaxial geogrids are geosynthetic materials that provide equal tensile strength in two directions. These are critical in applications such as road construction, foundation stabilization, and retaining wall support.

The benefits of using biaxial geogrids include:

- Prevention of Soil Movement: Helps reduce settlement and improves soil retention.

- Extended Infrastructure Lifespan: Roads, railways, and embankments last longer when reinforced with biaxial structures.

This biaxial structure ensures optimal performance under traffic loads, environmental shifts, and heavy equipment usage.

Biaxial Stretching in Manufacturing

Another important industrial use of the biaxial concept is in biaxial stretching, particularly in the production of plastic films like PET, BOPP, or BOPA. In this process, the material is stretched in both the machine direction (MD) and transverse direction (TD), which improves its mechanical properties and optical clarity.

Applications of biaxially stretched films include:

- Food Packaging: Improved barrier properties, transparency, and toughness.

- Electronics: Used in displays and flexible circuits.

- Medical Packaging: Sterile environments require high-performance films.

Biaxial stretching results in films that are thinner, stronger, and more flexible—critical characteristics for advanced product applications.

Biaxial Systems in Medical Devices

In biomechanics and medical device design, biaxial simulation helps in understanding the behavior of tissues or organs under stress. For instance, artificial heart valves or vascular grafts are often tested under biaxial stress to simulate how they’ll perform inside the human body.

Medical innovations that rely on biaxial principles include:

- Heart Tissue Implants: Mimic the real movement of the heart walls.

- Orthopedic Implants: Devices for knees or hips that must endure complex movement.

- Skin Grafts: Biaxial expansion helps understand stretching limits of artificial or donor skin.

In these applications, the human body’s multi-directional movement is best replicated through biaxial stress tests and designs.

Biaxial in Mechanical Design

In mechanics, a biaxial joint or mechanism can rotate or move along two axes. This feature is used in many devices, including:

- Robotic Arms: Biaxial joints offer better freedom of movement.

- Camera Mounts: Biaxial gimbals stabilize the camera in both vertical and horizontal directions.

- Aircraft Control Surfaces: Systems that adjust simultaneously in pitch and yaw.

The design flexibility that biaxial systems provide is essential for precision engineering.

Biaxial in Optics and Crystals

In the realm of optics, certain crystals are termed biaxial when they have two optical axes. These materials, such as mica or gypsum, behave differently from uniaxial crystals and require specific alignment and handling.

Biaxial optical properties influence:

- Refractive Index: Light behaves uniquely in biaxial materials.

- Material Identification: Geologists and chemists use biaxial characteristics to identify minerals.

The unique light behavior in biaxial crystals makes them essential in laboratory optics and spectroscopy.

The term biaxial might seem simple at first, but its applications stretch far and wide across modern science and technology. From material science and civil engineering to medical technology and optics, the principle of two-directional response and reinforcement defines a new standard in durability, safety, and performance.

By leveraging biaxial systems—be it in testing, manufacturing, or design—engineers and innovators ensure their products stand strong in real-world applications. As industries continue to evolve, the relevance of biaxial principles will only grow, laying the foundation for more robust, adaptive, and intelligent solutions.